Chemical composition

The chemical composition is the fundamental quality indicator to all our abrasive ,which determines the micro structure and the final result of heat treatment. Germany QUANTRON direct reading spectrog

A.raw materials

All raw materials are qualified products with product testing reports.

B. molding

In the production process, molding is the key of product quality . On the

furnace temperature control, the number of units and raw materials scattered

uniformity, the introduction of wind and other equipment in strict accordance

with the operating procedures.

C.annealing

annealing is the necessary way to improve the strength of the product, the

temperature is critical. We strictly according to set temperature, the annealing

speed can not be fast, nor slow, to ensure the timeliness of the annealing

process.

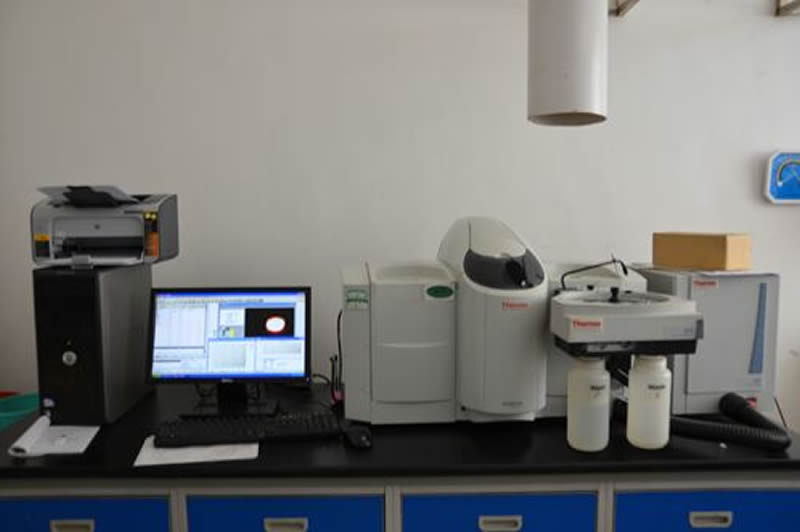

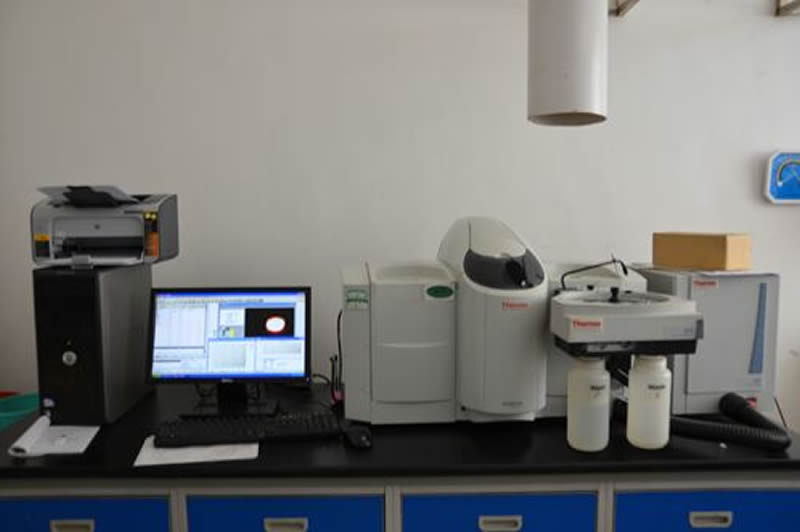

D.test

We use advanced detection equipment, to control the step quality , substandard

products can not be stored.

All the product reach international standard , like European EN1423 and 1424,

the United States AASHTO M247, the British BS6088, Japan JIS R3301, South Korea

KS L2521 and other requirements.

The chemical composition is the fundamental quality indicator to all our abrasive ,which determines the micro structure and the final result of heat treatment. Germany QUANTRON direct reading spectrog

The consistent harness of all our abrasive is the key to make acting force work idealy, also has a great effect on working efficiency and consumption of abrasive media.

The state of all our abrasive microstructure determines the fatigue resistance performance high or low. Nice microstructure makes all our abrasive higher impact resistant ,which largely extends the

Every size sall our abrasive the mixture of particles which size ranges. The number of all our abrasive from unit weight determines the kinetic energy of all our abrasive. Proper number can produce moderate kinetic energy and moderate coverage.

The Life Testing Machine is used for testing the value of all our abrasive fatigue life and the range of kinetic energy,which is the ultimate embodiment of steel shot quality.

We can test the clean level after surface treatment, the roughness and the surface strengthening thickness value after strengthening,helping users vertify the treatment effect.

Our philosophy is to build growth on a foundation of high quality, excellent service, We product according the ISO quality standard. and in-depth application knowledge. Highly efficient logistics are central to the company’s culture, and Junda tight control of materials, from source to user, to ensure quality and consistency.